Flipflopi partners with Delft University of Technology to accelerate solutions for problematic plastics

We were very excited to receive Robin, Tosca & Rykiel, Design Engineering graduate students to come and support our research on problematic plastics and share some of their experiences so far. Read more below!...

As 3 Masters students of Industrial Design Engineering at the Delft University of Technology, we wanted to do something for the greater good - to design something for people that was really needed. The world is changing a lot and we feel it is our obligation to use our skills to contribute to a better world.

Flipflopi came to our attention through friends that had visited Lamu in the past, and after the initial call with Katharina (Designer & Recycled plastic expert) and Leonard (Chief Engineer) we said: Let's go! The excitement and passion for what they do was infectious!

During our first few weeks we were welcomed in true Lamu style, meeting many genuine people and participating in the Bahari Yetu (“Our Ocean”) Festival, which brings much-needed attention to ocean preservation. The urgency to address all the waste here becomes clear as soon as you take your first steps on the island, and is highlighted by the vast plastic mountains that have built up at Flipfopi’s Recovery and Recycling facility.

The plastic system

During our first week we became acquainted with the ins-and outs of the lengthy plastic recycling process. It started with community collections enabled by a ‘tinga’ (tractor); we then helped with sorting - a critical point in the process where multiple types of plastics are separated from one another. We quickly realized though, that it is not just product development, it is a whole system that you have to take on, and the Flipflopi team have taken on this responsibility for a large part of the Lamu archipelago.

From collection to sorting, washing and recycling production, they are doing it all here. In essence, Flipflopi has become, in part, a big Research & Development facility (enabled by the Sustainable Manufacturing and Environmental Pollution Program, SMEP) that handles multiple plastic streams and develops circular processes and practical manufacturing solutions for multiple products.

But that does not mean it is easy to do or to set-up. One of the biggest plastic piles on the archipelago of Lamu is made up of ´Magunias´ which are a common type of plastic woven sack used for transporting almost anything in this region. ‘Ma’ means a lot, ‘Gunia’ is the term for the bags. FlipFlopi has already collected 35 tonnes of it, but is still in the process of finding the best method to get the best second life for this material.

The challenge of processing ‘magunia’

First of all, it takes a huge volume of gunia bags to create the recycled plastic product. In order to process 1 KG of recycled material, you need approximately 11 large sacks, which is a huge pile to process. So even if you first shred the material, the volume remains significant.

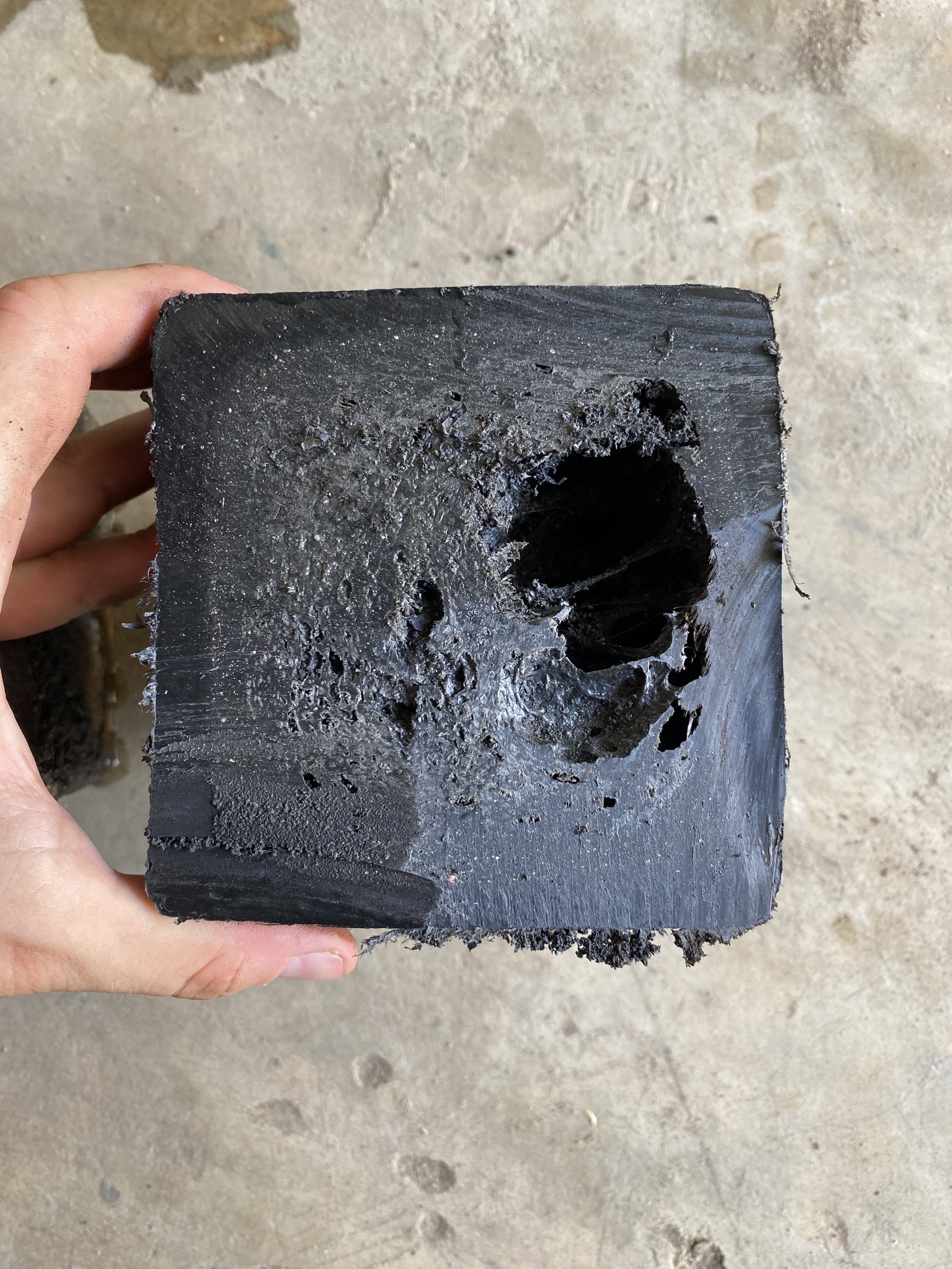

One solution to overcome the gunias volume issue is to use an agglomerator. This machine cuts the bags, around 25 KG per batch, fed in through the top by a rotational force. Due to the speed of the knives inside, the plastic heats up and starts to clump. This process can take roughly 30 minutes when the machine has just started running, but after an hour it will only take 7 minutes. So sounds pretty easy but even this carries multiple challenges…

You have to be highly skilled to know how much you should feed the machine. If you feed in too many bags, the machine will not take it. Or, if you agglomerate for too long, all the plastic will melt together in one big lump. The machine is quite loud, and spits out a lot of dust during the process. So ideally for upcycling magunia, we would like to skip the agglomerator altogether, because it requires a lot of time, energy and training. In short: it’s not ideal.

If you do manage to get good output out of this agglomerator, It’s possible to feed it back to the extruder to process it into planks. However, the extrusion process to produce good quality lumber is also challenging because of the nature of the plastic used in the bags which can differ from brand to brand and is often polluted by mixed plastics, additives and dirt (even after washing). This results in air bubbles inside the lumber, and leads to differences in viscosity and melting temperature.

From an aesthetic point of view, the agglomerated material is mixed and loses its color. Also, porous lumber containing air bubbles does not have the same strength as solid lumber. So currently extrusion is also not the best process for this particular complex material though ongoing trials have made some improvements but not up to the high quality standards that Flipflopi has set for itself.

Then there is the commercial aspect: very few facilities in the industry are willing to buy or recycle magunias because it is such a low quality material and the price they offer is very low. Flipflopi is trying to determine the viability of circular solutions for the most abundant plastics on an archipelago that is geographically quite far from major cities.

So if it is this hard to do, nobody wants it, what should we do with it and how should we treat it?

This is where the tenacity of the Flipflopi team comes in since the team can visualise the need - and potential - in making products from these common sacks, and are working hard to make it a reality. So we carry on with testing and exploration…

Testing, testing, testing!

Since the extrusion of magunias does not result in the best quality lumber, we are now looking into the process of melting them into sheets, which has some advantages over the other processing techniques. These sheets, depending on the size, can be used for a lot of things. To produce these small sheets we use a sheet press and different mould types to see what gives us the best results.

Alongside doing the tests, we are also looking into how sheets can be used. We spoke to people about their perception of plastic products/furniture, and how they would use it in their local context, for example in schools. We are currently documenting all our findings of our results and ideas to upscale a sheet press for scaled up production in Lamu.

Changing the plastic landscape

So - after two weeks spending time with these recycled plastic experts, we learned quite a bit about the possibilities and the challenges. Asking questions and co-creating new solutions with the local community is a must, and a pleasure to experience. Certainly the way of working was very different to what we are used to and a lot more hands-on: the ethos here is to get your hands dirty and try new things with the resources that are available here.

Our overall goal is to continually learn about the properties and application of magunia. We need evidence based information to better inform the government, the industry and individuals about how to give these bags a second life or whether it is even really possible so that better standards are enforced at the primary manufacturing stage or substitutes are found that are more circular.

Thank you Flipflopi

It is quite beautiful to see how this organization is changing and trying to improve itself all the time. Even in the three weeks we are here you literally see the change.

When we leave, we hope that we will have contributed to the knowledge of magunia and that we are able to share some guidelines on how to upscale our research at FlipFlopi. We truly believe that FlipFlopi has huge potential to change the plastic landscape.

For now, many thanks to FlipFlopi for their generosity and energy!

Robin, Tosca & Rykiel