A lesson on building boats (from recycled plastic)...

By Katharina Elleke

Coming to Kenya nowadays, I can't miss Lamu on my to-do list and catch up with the Flipflopi dhow building crew, see how things are going, what the current issues are, where I can contribute my skills and knowledge (and of course have the chance to sail with Captain Ali and team on his dhow :)

I guess it lies in the nature of industrial designers like me to be interested in manufacturing processes and materials. Now, I would say, I do know quite a bit about plastics and recycling processes - from washing, sorting and shredding, to melting, shaping and other techniques. But I didn't know a lot about building boats! now I can at least add "how to build dhows" on my list of "things I know a bit about and would like to learn more (it's a long list!)

So, first of all, being there and helping with chopping recycled material, drilling holes and putting in screws, it was really impressive to see the basic, handmade tools they use!

Although plastic is of course a very different material, you can work with it in a similar way as you would with wood. That's also one interesting aspect of this dhow's building process: swapping the material but keep the tradition. And as I wanted to work a bit more with the material, we decided to start making handles for the steering wheel. Same machines and process, different materials. And another thing to check of the checklist for flipflopi dogo (who is soon to set sail)

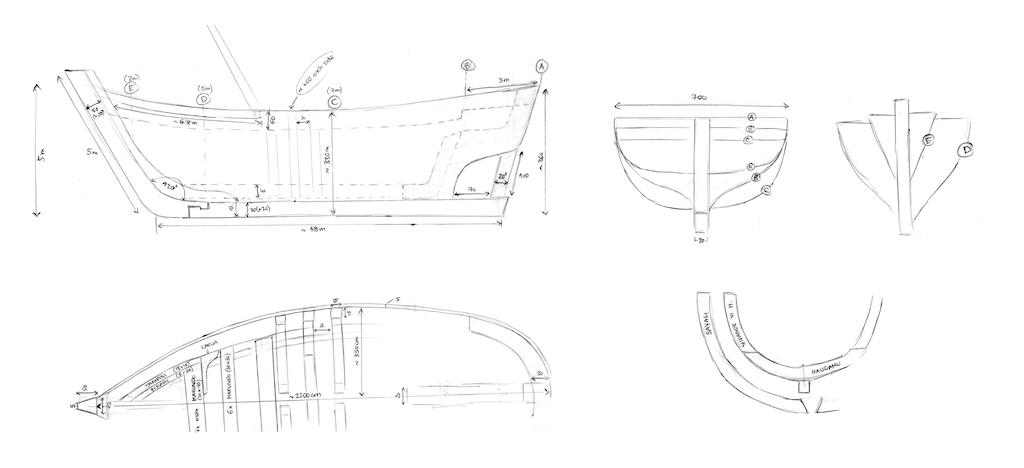

I always wondered how Ali actually plans and builds a dhow. Every model he makes is different as he is trying out various styles and techniques. So, how does he know which shapes the parts would have, which lengths or angles? When I design something, I am used to making detailed sketches and plans with exact measurements foar everything, so that in theory, anyone with the plans is able to make my product. Even though Ali makes a lot of sketches with (estimated) measurements and descriptions, there is so much more to the process that is so hard to capture on paper but so well understood in the minds of the dhow builders...

When building a dhow and probably in most traditional boat building processes, one part comes after another and all the pieces are shaped during the process. You cannot know the exact measurements for every rib before having outlines the keel and outer shape. After that, the planks, after that the Sayali, then Firari and after the Firari, the Tampisi, etc. All handmade and step by step.

It seemed tricky to make the detailed plans and blueprints for the Flipflopi in advance. Even impossible if I'm working on it from somewhere else, only having Ali's sketches in front of me. So we spent a couple of evenings (or rather nights) to build the Flipflopi Dhow - in digital! (Of course, very exciting for people like Ali and Hassan, who both never even really used a computer before!)

Starting with a bit more detailed blueprint, we then built the dhow in 3D as if we were building it in real. A beautiful collaboration of their experience and know-how and my CAD skills! It's still work in progress, but the main structure is done, so that we can now take measurements and shapes from this 3D-Model to make further planks and calculations from the REAL big dhow that will one day, sail from Lamu all the way to Cape Town!